Architectural

Specifications

To achieve the vision and design intent of

architects and interior designers and ensure

contractors can plan accordingly, here are the

specifics of how FORGED are designed,

engineered and manufactured by VAULT®.

Exterior Finish

VAULT® is best known for the quality of our finish work and use of high-performance powder coating for architectural applications. Committed to offering a stylish product is where we excel from other metal cabinet manufacturers.

Manufacturing – No visible seams or soldered joints are exposed. Visible surfaces are painstakingly critiqued to eliminate unsightly welds and fasteners and to provide joint seams and reveals that are highly precise and consistent. All exterior surfaces are hand sanded prior to powder.

Powder Coating – A vast selection of durable, scratch resistant, easy to clean surfaces ensures a professional finish for virtually any interior architectural application where the highest level of protection of your design is required without compromising aesthetics.

Quality Control – Exposed surfaces have a ‘Class A’ finish that is visibly-free of scratches, nicks, dents, dings, creases, chipping or peeling or other surface imperfections on exposed surfaces when observed at a distance of 3 feet. Dents, dings, creases, chipping or peeling are not allowed on any exposed surface.

Standards – We factory apply a full line of advanced powder coatings that provide superior finish quality that are a sustainable option that meet or exceed AAMA and EPD specifications:

- Meets and exceeds AAMA 2605;

- Independently verified Environmental Product Declaration (EPD) can contribute to LEED points and other sustainability initiatives.

Color Choices

Beautifully detailed in furniture-grade powder coating our premium base coat/clear

coat finish projects a luxurious, deep gloss that is a signature feature that has made our

cabinets famous. We offer trade professionals complete creative freedom to select

colors, metallic flake and sheens to create a limitless number of possibilities to

personalize the cabinets for their client.

Raw Materials

Cabinet interiors are available in your choice of 304-Grade Brushed Stainless Steel or

Premium-Grade Galvanized Zinc Coated Steel. Both metals are known for their excellent combination of long life, strength and protection from rust better and are the best raw materials from which to build cabinet interiors that will last a lifetime of use.

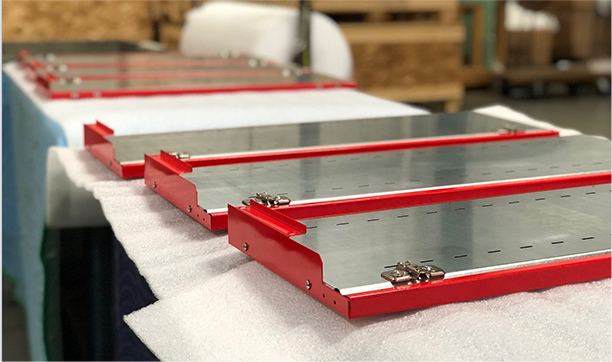

Drawer Construction

Drawer are constructed from 20-Guage (.036″) metal in your choice of 304-Grade Brushed Stainless Steel or Galvanized Zinc Coated Steel. Exterior cabinet drawer faces are made from Powder Coated 20ga. (.036″) Cold Rolled Steel. Drawers can be constructed up to 48” in overall width.

Drawer Operation

Drawers operate smoothly on Industrial-Grade Stainless Steel Ball Bearing Drawer Slides (200lb Full-Extension) that easily accommodate extreme (up to 200lbs/per drawer slide), without any noticeable fatigue in their operation. Using extreme-duty hardware prevents drawers from being damaged, ensuring they will open and close in proper alignment for the lifetime of cabinet ownership. Full-extension drawer operation allows easy access to the furthest reaches of the drawer, providing easy accessibility to all contents.

Shelf Construction

Shelves are constructed from 16-Gauge (.064") metal in your choice of 304- Grade Brushed Stainless Steel or Galvanized Zinc (G90) Coated Steel. Using this thick gauge of metal reduces scratches, nicks and dents. Each shelf is spot-welded for additional strength to accommodate 400lbs of weight per shelf with no deflection (bend) in the panel.

Building a shelf to this standard of quality ensures they will last a lifetime of use without buckling or warping from the constraints of weight. Shelves that are 36“-wide or wider have stiffening flanges to increase weight load capacity and can be constructed up to 48” in overall width.

Shelf Bracket Construction

Shelf brackets are made from thick 14-Guage (.079”) metal so clients will never have to worry about shelf failure. Brackets run the full depth of the shelf and are adjustable every 1/8” so clients can place shelves where they are needed and minimize any wasted space.

Standard construction is stainless steel when 304-Grade Brushed Stainless Steel interiors are selected or G90 metal when Galvanized Zinc Coated Steel interiors are selected.

Quantity Of Shelves

The standard number of shelves are four (4) adjustable shelves per Armoire cabinet and one (1) adjustable shelf in Base, Wall and Overhead Storage cabinets. Clients can order as many additional shelves as are needed.

Door Construction

Doors are welded double-wall construction using Powder Coated 20-Guage (.036” Cold Rolled Steel with stiffening flanges built in place to create a stronger, rigid door. How impressive is our solid door construction? A single Armoire door weighs an astounding 48”! Building doors to this standard of quality reduces scratches, nicks and dents. Single doors may be mounted left or right-hinged operation.

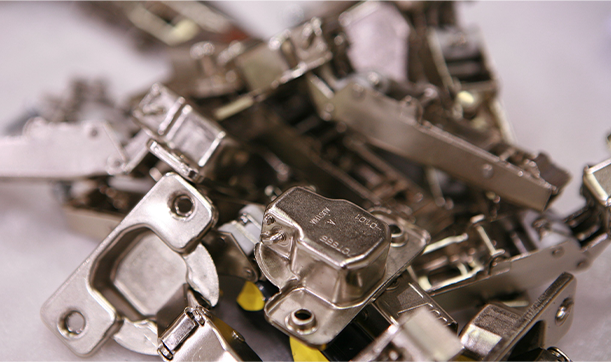

Soft Closing Fully Adjustable Hinges

Top performing fully-adjustable hinges by Blum guarantee that all doors remain in perfect alignment. The soft closing mechanism lets clients control the speed at which they want doors to close. Magnetic latches keep doors tightly closed until you need them opened and seals the inside of the cabinet from dust, insects and varmints and keep doors tightly closed until you need them opened.

Wall Mounted Brackets and Cleats

Our full length brackets and cleats are made from indestructible 11-gauge (.123”) Galvanized Zinc Coated Steel. After the wall brackets are firmly secured to studs the reverse cleats on the back of the cabinets allow them to be easily and firmly seated.

This type of installation ensure cabinets stay straight and true so that no door, drawer or shelf ever comes out of square or alignment. Using four (4) hanger brackets per Armoire and two (2) hanger brackets for all Base, Wall and Overhead Storage Cabinet ensures cabinets are rigid and can dissipate extreme weigh-load capacity.

Quality Management System

Each cabinet is finished by hand by our assemblers who take the utmost care to provide the exact options specified on each order. Our design processes are controlled and audited to assure we meet our customer’s requirements and that the outputs of that design are sufficient for our in house manufacturing to produce parts to a client’s specification.

The design and development and manufacturing of FORGED© Cabinets complies with the requirements of ISO 9001:2015 for fabricated sheet metal products and complies with the requirements of ISO 13485:2016 for the manufacture of surgical trays, (instrument cases / trays / cassettes), for the area of orthopedics.

Lead-Time

Our shop is a consistent 6-7 week lead-time from the time a deposit is placed until order is ready for shipping. Customization can add onto the lead time of an order depending on the complexity of the request.